Tramming is the process of squaring the head of your milling machine to the table. If your mill is not trammed properly, surface finishes will be poor and parts will not be flat or square. The Pro Tram makes the process of tramming your milling machine fast, easy and accurate.

Calibration

To account for the error caused by inconsistent collet seating in the spindle, it is recommended to check the calibration of the Pro Tram Gage every time it is used. Completing the steps below will position the two indicator tips on a theoretical line that is perpendicular to the spindles axis.

• Install the Pro Tram into spindle.

• Place calibration magnet on the table under one of the indicators.

• Lower spindle until indicator is depressed about 0.100”. Then lock the spindle in place. Be sure to lock the knee of the mill as well.

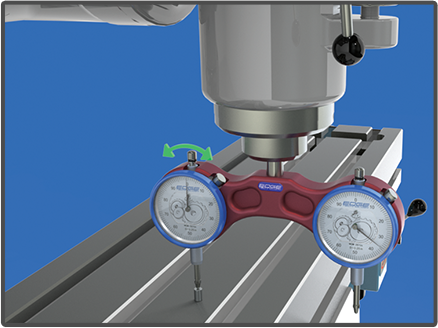

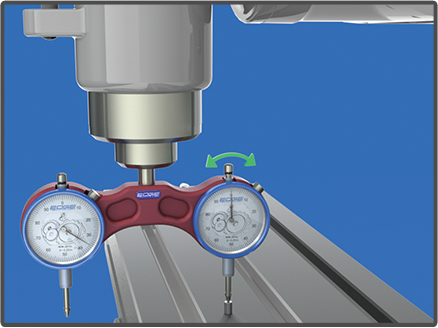

• Rotate the face of the indicator until the needle reads zero. Then rotate the Pro Tram unit 180 degrees so that the other indicator is contacting the calibration magnet.

• Rotate the face of the second indicator until the needle reads zero.

• After calibration the right and left indicator faces may be rotated to slightly different positions. This is caused by a slight variance in indicator length and will not affect the functionality of the unit.

Operation

• Install the Pro Tram into the spindle. Lock the knee of the mill.

• Position the Pro Tram parallel to the length of the milling machine table. Then lower the spindle until both indicators are depressed by about 0.050”.

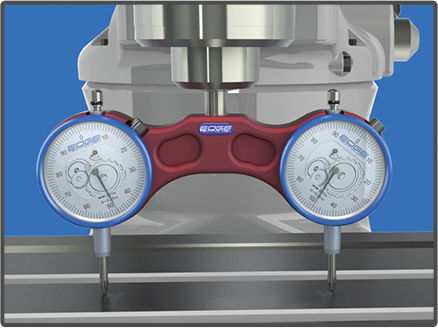

• Make adjustments to the head of the milling machine until both indicators read the same number. When this is accomplished the first axis of the milling machine is trammed.